新型 Tier 1 定位

深圳市卓驭科技有限公司专注于智能驾驶系统及其核心零部件的研发、生产、销售等业务,为汽车行业智能化提供灵活多样的解决方案。凭借多年积累的感知、机器学习、定位、决策、规划、控制技术研发与量产经验,与合作伙伴一道推动高阶智能驾驶的全面普及。

全新一代智能驾驶解决方案

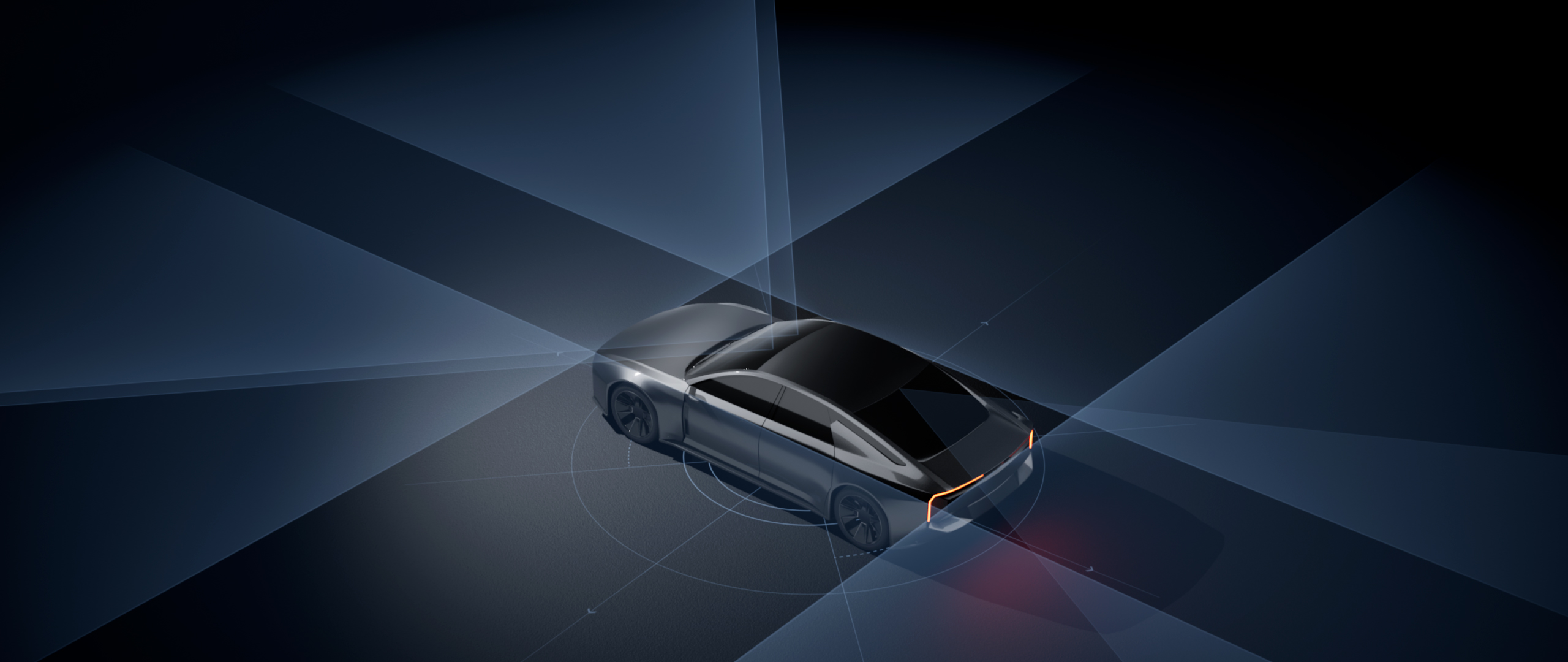

成行平台以 32 至 200TOPS 的灵活算力配置,7V/10V/12V 的简洁传感器配置,实现了包括高速领航、城市领航、城市记忆领航驾驶在内的高阶智能驾驶功能。成行平台基础版本提供了亲民普惠的高阶智能驾驶可用体验;支持灵活增加算力,拓展高精地图、激光雷达等传感器提升舒适性,增加安全冗余。并支持多样化的产品交付模式,满足不同定位、价格车型的市场需求。

成行平台可以按需拓展激光雷达、高精地图

卓越的高阶智驾产品研发及工程能力

智驾控制器、传感器等全栈硬件设计、开发、测试验证、生产制造能力。

领先的智能驾驶全栈算法研发能力。

规模化、自动化基础设施,支持智驾体验高效迭代。

车规安全操作系统开发能力,符合 ISO 26262 功能安全要求。

量产软件不含 FOSS,杜绝开源软件缺陷风险,全系统安全可控。

高标准交付

我们从供应链管理能力、质量保证能力,新产品开发能力三个方面着手,结合自身特点与汽车行业要求,打造了一套车规级管理体系。在实践中不断改进优化,为客户提供低成本、高质量、高性能的智能驾驶产品。

车规级工厂

智能制造与检测中心专注于视觉感知系统、域控制器、激光雷达等智能驾驶核心零部件的一站式制造与检测,致力于用空间智能科技赋能出行,拥有覆盖全系、功能强大、国际先进的高端设备、仪器,具备理论扎实、技术过硬、多年汽车行业经验的人才团队,依靠 PLM、MES、ERP、EAM、QMS 等信息系统支撑,按照工业 4.0 理念,努力成为国际一流的车规级智能制造与检测中心。